0755-83687076

Author: admin Time:2021-12-15 Click:

Harting is committed to achieving excellence in modularity, flexibility, and speed with its "Total PCB" solutions

Espelkamp, November 24, 2021 — The importance of modularity and flexibility in equipment development is increasing: digitalization and industrial transformation trends are shortening the development time for new equipment, while the role of prototyping is becoming more significant. Additionally, the insufficient number of standard components available often affects equipment development. Harting's PCB connectors meet the industry's demands for modularity, flexibility, and speed in equipment development.

This solution, named har-modular®, is a modular PCB interface that any developer can configure online individually. This means that whether it's rapid prototyping, small series production, or full product ranges, the workload for equipment developers is significantly reduced. The modular construction components, with a billion possible combinations, are almost perfect. Custom solutions with a minimum order quantity of one not only save development time, costs, and effort but also help to shorten the process of producing new industrial equipment. Developers can adjust the connectors to their needs, rather than the other way around.

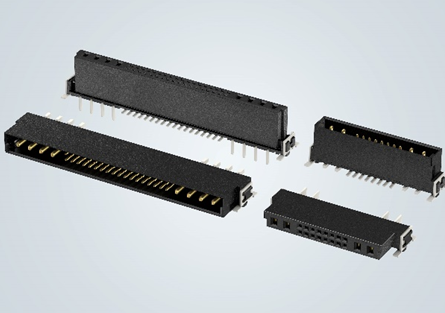

Har-flex® connectors cover a range of pin counts from 6PIN to 100PIN and can meet the transmission requirements for signals, data, and power. Their 1.27mm pitch design conforms to the trend of connector miniaturization. They can accommodate different board-to-board stack heights and are suitable for wiring applications in compact spaces. The product meets the high-quality welding requirements for miniaturized PCB applications during welding.

Text Description: har-modular® embodies the concept of a modular building block system, achieving a billion possible combinations through different modules.

The translated English text for the image would be: "har-flex® — Especially suited for miniaturized PCB applications."