0755-83687076

Author: admin Time:2021-12-15 Click:

Photovoltaic/wind energy power generation and storage systems, electric vehicles, and charging stations, industrial variable frequency control systems, and many other energy-saving and carbon reduction applications have become powerful tools for achieving the goals of "carbon peak" and "carbon neutrality". In these electronic and electrical power systems, the key components that control power consumption are the tiny power semiconductor devices.

Small size, big effect

Power semiconductors are the core devices for achieving electrical energy conversion. They can effectively control the application of voltage and current, and through changes in the switching state, they can realize various functions such as inversion, rectification, and frequency conversion. These devices control the energy output of electronic power systems, minimizing the energy consumption of the entire system, thereby achieving rational energy management, reducing energy consumption, and reducing carbon emissions.

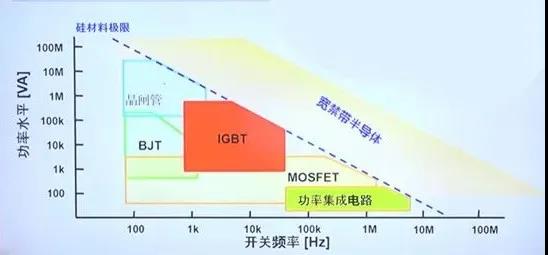

The different structures of power semiconductor devices determine their different switching frequencies, power levels, and breakdown field strengths, which also determine the application scenarios of different types of power semiconductors. Thyristors, IGBTs, and MOSFETs are the three most common types of power semiconductor devices currently available in the market. Due to their small required drive power and fast switching speed, silicon-based MOSFETs dominate applications below 600V. On the other hand, silicon-based IGBTs have become popular in the high-voltage application market ranging from 600V to 6500V due to their low conduction losses, fast switching speed, high voltage rating, high working junction temperature, and convenient drive.

Based on their structures and functions, power semiconductors have become core devices in various fields such as power generation, transmission and distribution, and power consumption. For example, in the fields of power generation, devices like photovoltaic inverters and wind power converters; in the field of transmission and distribution, devices like DC converter valves, AC/DC circuit breakers, and unified power flow controllers; and in the field of power consumption, devices like electric vehicle drives, electric locomotive drives, charging stations, energy storage converters, industrial frequency converters or inverters, etc., all rely on power semiconductors to play a prominent role. As devices for controlling power, reducing energy consumption and improving energy conversion efficiency are the main directions of development for power semiconductor devices.

In addition, power semiconductors have also brought new development opportunities for energy conservation and carbon reduction. According to Xiang Jie, Chairman of Saikong Technology Group Co., Ltd., power semiconductors can create new ways of producing and applying electricity, such as electric vehicles, wind power, photovoltaic power, electrification in industrial and civil fields, thereby reducing the use of fossil energy. The use of power semiconductors can improve energy efficiency, such as frequency conversion energy saving and DC transmission, thereby saving energy losses.

IGBT becomes mainstream, domestic manufacturers catch up

IGBT has many advantages, including high input impedance, small control power, simple drive circuit, fast switching speed, large conduction current, low conduction voltage, and low loss, which gives it an absolute advantage in the current market environment. IGBT is a switch device that is either on or off, and its off state is controlled by the change in the gate-source voltage. It can adjust voltage, current, frequency, phase, etc., according to the signal instructions to achieve precise control.

Therefore, IGBT has become the most mainstream device in the current power semiconductor market and is widely used in many fields such as new energy power generation, electric vehicles, charging stations, electrified ships, DC transmission, energy storage, industrial control, and energy conservation.

However, the main players in the global IGBT market are still mainly overseas top companies. Infineon, Mitsubishi, and Fuji, the three giants, account for 70% of the IGBT market share. Domestic IGBT manufacturers have already started, but to achieve further technological and market breakthroughs, there are still significant challenges. According to Dr. Bai Ran, a researcher at the Integrated Circuit Center of CCID Consulting, the technical route of IGBT has always been led by Infineon. Infineon's products have already reached the seventh generation, while domestic IGBT technology is only at the level of Infineon's fourth and fifth generations.

In order to shorten the gap with overseas advanced levels as soon as possible, domestic power semiconductor companies are accelerating their layout in the IGBT field and are working hard to improve their product performance and expand their market space. Among domestic power semiconductor companies, BYD Semiconductor, CRRC Zhuzhou Locomotive Co., Ltd., CETC Semiconductor, and Staic Semiconductor have shown outstanding performance.

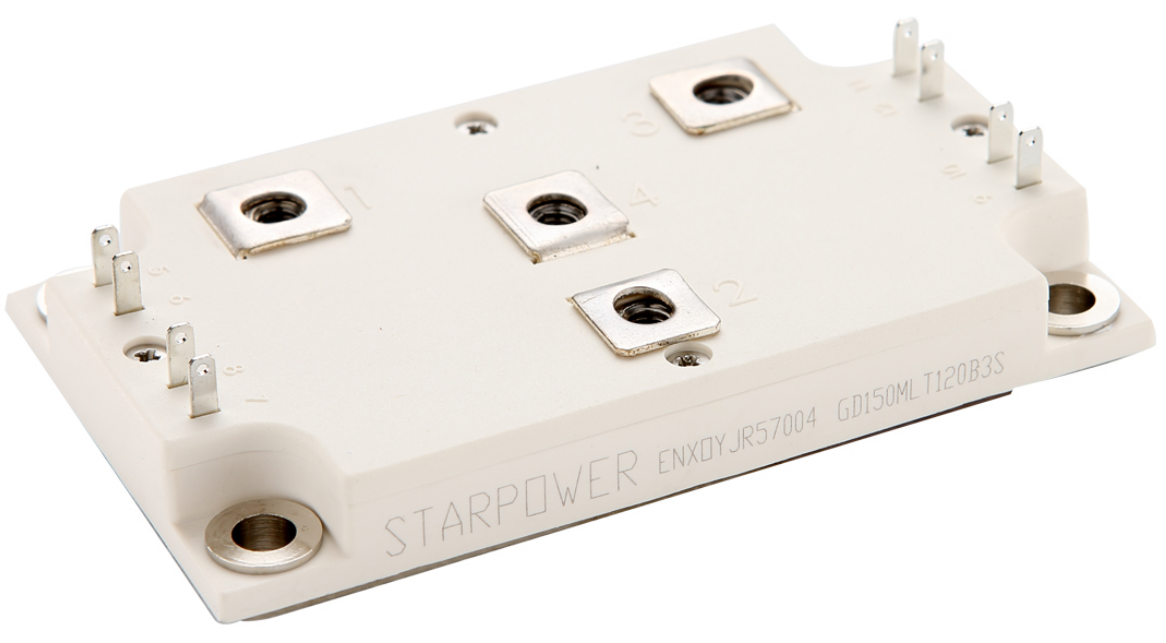

BYD Semiconductor has laid out the whole industrial chain of IGBT products and has performed well in the automotive field, accounting for 18% to 20% of the domestic new energy vehicle market share. Jiaxing Staic Semiconductor started early in 2008 and has a high technical starting point. It currently has a variety of IGBT module products with specifications of 600V/650V/1200V/1700V/3300V, as well as MOSFET, IPM, FRD/rectifier module, thyristor, and other types of products, with a relatively rich range of product types. In addition, Zhuzhou CRRC Times Electric Co., Ltd. has made plans in the fields of smart grid, automotive, and new energy control, and its market share is about 1% of the entire automotive market, with great development potential. In addition, CRRC and CETC Semiconductor have also positioned IGBT as a product line.

Two-wheel drive: Optimize packaging and application of wide bandgap semiconductors

Data Source: Infineon China IGBT Course

China has the world's largest power semiconductor market, contributing about 35% to 40% of the global power semiconductor market, which is worth approximately $50 billion. During the "14th Five-Year Plan" period, the evolution of the next-generation information technology represented by cloud computing, mobile internet, big data, and artificial intelligence will generate a higher demand for power management products. The goal of "carbon peak" and "carbon neutrality" has been proposed, and the fields of new energy power generation, electric vehicles, charging stations, and industrial electrical control are rapidly developing, driving the growth of the IGBT and MOSFET industries.

For domestic enterprises, the increasingly expanding domestic market undoubtedly provides a broader space for development. Regarding how to seize market growth opportunities, how to leverage the momentum to achieve industrial breakthroughs, and how to enhance product performance, Bai Ran believes that optimization of device structure and innovation in substrate materials can be used as a two-wheel drive approach, which represents an opportunity for domestic companies.

Yang Qinyao, Vice President of BYD Semiconductor Co., Ltd., told China Electronics News reporter, "Higher power density, switching frequency, smaller conduction voltage drop, switching loss, chip size, and module volume are the technical development directions for future IGBTs." In the journey to enhance the performance of power semiconductor products, silicon-based devices face a limit in terms of power level and switching frequency due to the inherent limitations of silicon-based materials. At this point, wide bandgap semiconductor materials such as SiC and GaN become a new track for further enhancing the performance of power semiconductor devices.

Due to the current challenges in wide bandgap semiconductor manufacturing, such as high difficulty, low yield, and high cost, they are mainly used in high-value-added products with high reliability requirements, such as vehicles. These products align with the development of many fields related to the "dual carbon" goals, such as new energy power generation, electric vehicles, and industrial electrical control. These industries require high stability in power management and high frequency power semiconductors, becoming the core direction for the layout of wide bandgap semiconductors. With the significant promotion of reducing carbon emissions brought by new energy electricity, electric vehicles, and industrial electrification, the domestic IGBT industry has the opportunity to "change lanes and overtake" with the help of wide bandgap semiconductors.

Currently, wide bandgap semiconductor manufacturing is challenging, with low yield and high cost. For products that are sensitive to price fluctuations and have low added value, the enhancement of power semiconductor performance can start with optimizing the packaging method. By adopting more advanced modular packaging, optimizing heat dissipation performance, and increasing junction temperature, the packaging can be optimized to improve the efficiency of module usage.

TrendForce analyst Gong Ruijiao also believes that domestic companies have the potential to surpass competitors in advanced packaging and wide bandgap semiconductors. He said, "From the perspective of industrial characteristics, power semiconductors are specialty process products that emphasize process technology, packaging design, and material iteration, rather than chasing Moore's Law. Therefore, domestic companies have a very good opportunity to surpass competitors."